TRM-120 / TRM‐130B

- Facility overview

- This is a machine that expands the inner and outer diameters or rolls the shape of cylindrical products by cold rolling by mandrel and forming roll.

- Rolling quality

- Metal flow is formed according to plastic working, so there is little heat treatment deformation, so dimensions are stable and wear resistance is greatly improved.

- Cost reduction

- Material yield is improved by 20-30% for bearings.

- The life of the tool is long due to low cost, shortened C/T, and cold plastic working.

- Cold rolling range

- The product is rolled by about 20% of the outer diameter.

- Dimension control

- It is controlled by setting the range in multiple steps in the NC controller.

- Depending on the situation, sizing is attached to control the final dimension.

SPEC

| ITEM |

TRM-120 |

TRM-130B |

| Working range |

Maximum OD after rolling |

Ø20 ~ Ø120mm |

Ø25 ~ Ø140mm |

| Maximum width after rolling |

Max. 35mm |

Max. 45mm |

| Oscillation |

Feeding Sys |

Screw + Reducer |

| Feeding Control |

NC Control |

| Slide |

L.M Guide |

| Roll Size |

Max. Φ180mm |

Max. Φ200mm |

| Support Roll Size |

max. Φ250mm |

max. Φ280mm |

| Mandrel Slide |

L.M Guide |

| Loader |

Air Cylinder + L.M Slide |

Air Cylinder + L.M Slide |

| Back up Roll |

Not applied |

Applied |

| Sizing |

Option |

Option |

| Motor |

Roll Driving |

Cyclo Reducer 11kw, 4p |

Cyclo Reducer 15kw, 4p |

| Hyd' Tank |

2.2kw |

2.2kw |

| Floor Size(Hyd' tank Included) |

2,900 x 1,900mm |

2,900 x 1,900mm |

| Weight |

3,600kg |

6,600kg |

※ All specifications and dimensions above are subject to change for quality improvement without notice.

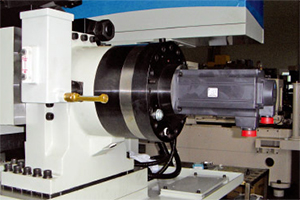

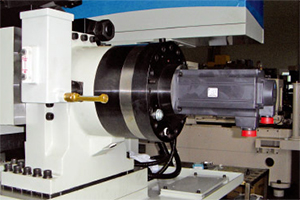

High-stiffness semi-permanent transport system

- Special Screw resistant to vibration and shock

- High rigidity Screw compared to ball screw

- Check and replenish internal lubrication

High rigidity, high efficiency reducer

- Reducer for high rigidity and high impact

- There is a big difference from the sexual tooth discrepancy

- Reducer suitable for high gear ratio

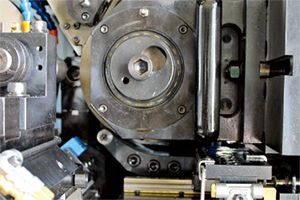

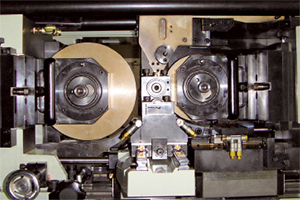

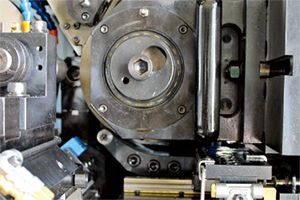

Improved roundness by installing back up roll

- Back up roll installation

- Excellent roundness improvement for shaped products

- Stable rolling with 3-point support

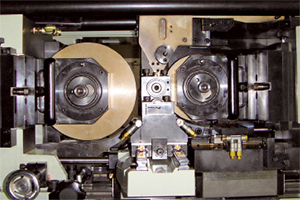

High rigidity LM SLIDE

- L.M GUIDE adoption

- Dimension control, mandrel, installed in 3 places of forming motor

- With triple seal cover

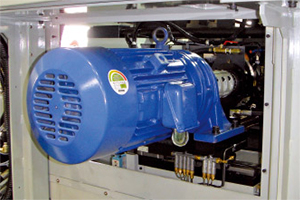

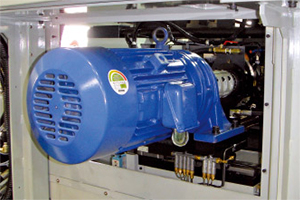

High torque molding motor

- Adoption of high-performance cyclo reducer

- Minimize load during transport according to molding

- Install LM guide

- Grid coupling: capable of absorbing impact force