High Technology TSG Grinder

TCG-200

- Minimized thermal deformation by deviding machine frame and coolant passage

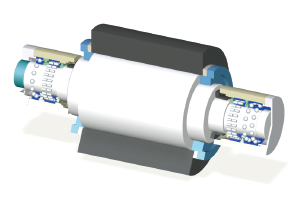

- High stiffness G/W R/W spindle result from both ends supporting

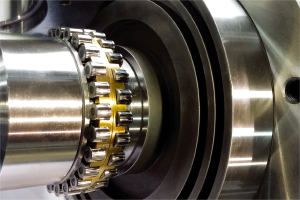

- Applying cylindrical roller bearing at G/W and R/W

- Easy to set due to the wider length of R/W

- Suitable for in-feed and thru-feed grinding for middle and small size products

- Keep clean by eliminating hydraulic tank